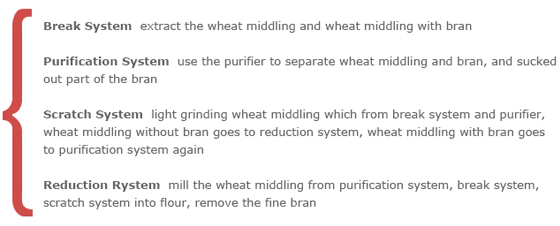

In order to ensure good flour milling effect, a complete flour milling plant need to separate the material of the different particle size and quality, thus forming different grinding system. Each system in the process of flour milling plays a role. There are five systems of flour milling plant: break system, scratch system, reduction system, purification system, tailing roll system.

Flour Milling Plant System

1. The role of break system is strip off wheat, scrape semolina, middling and dunst from wheat bran, and keep the bran not too much broken, so that the endosperm and wheat skin can maximize be separated, and a small amount of flour is sifted.

2. Scratch system processes semolina from break system and other system, makes endosperm and wheat skin separation further, sifts good quality of middling and dunst and feeds into reduction system.

3. The function of purification system uses screening and winnowing to separate the semolina, middling, dunst and wheat bran from break system and other system, and then sent to the corresponding grinding system processing respectively.

4. Reduction system is the system crushes middling and dunst get from break system, scratch system and purification system into certain fineness of flour

5. Tailing roll system is located in the mid-posterior, specialized processing containing wheat bran, poor quality middling and sift flour.